OH2 Petrochemical Process Pump

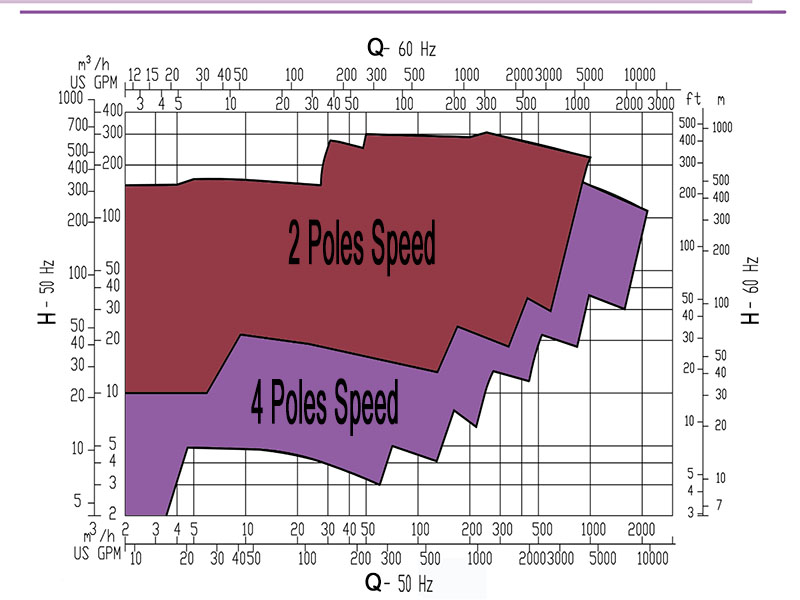

Operating Parameters

Capacity:2~2600m3/h(11450gpm)

Head:Up to 330m (1080ft)

Design Pressure:Up to 5.0Mpa (725 psi)

Temperature:-80~+450℃( -112 to 842℉)

Power:~1200KW

Features

● Standard modularization design

● The rear pull-out design enables the bearing pedestal including impeller and shaft seal to be removed with the volute casing left in position

● Shaft sealed by cartridge mechanical seal +API flushing plans.ISO 21049/API682 seal chamber accommodates multiple seal types

● From discharge branch DN 80 (3")and above the casings are provided with a double volute

● Efficient airfins cooled bearing housings

● High radial load roller bearing. Back-to-back angular contact bearings handle axial loads

● ZEO open impeller,adjustable bearing carrier allows for easy impeller clearance adjustment for high hydraulic efficiency, special design for slurry applications

● GB9113.1-2000 PN 2.5MPa suction and discharge flanges are standard. Other standards may also be required by the user

● ANSI B16.5 RF 300lb suction and discharge flanges are standard .Other standard many also be required by the user .

● The pump rotation is clockwise when looking from the drive end

● Jack screws (motor side) for an easier alignment setting

● Bearing lubrication and cooling options:Oil mist /Fan cooling

Application

Oil and Gas

Chemical

Power plants

Petro chemical

Coal chemical industry

Offshore

Desalination

Pulp and Paper

Water and Wastewater

Mining

Cryogenic Engineering